Introduction

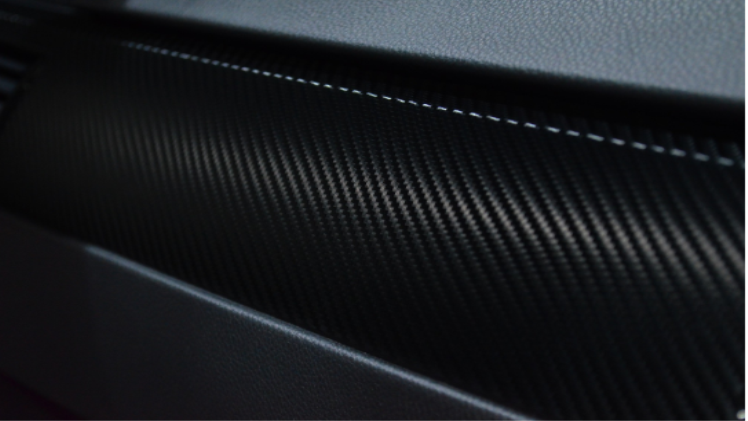

Carbon fiber is celebrated for its exceptional strength-to-weight ratio and durability, but traditional carbon fiber has always been expensive, limiting its widespread use. However, Aerolite carbon fiber is changing that narrative by offering a more affordable alternative without compromising on quality. So, what makes Aerolite carbon fiber so cost-effective?

Streamlined Production Process

- Thermoplastic Resins: Unlike traditional carbon fiber, which uses thermosetting resins, Aerolite uses thermoplastic resins. Thermoplastic resins are less complex to work with because they can be softened and reshaped with heat. This characteristic simplifies the manufacturing process, reducing time and costs associated with molding and curing.

- Efficient Manufacturing: The production process for Aerolite carbon fiber is more streamlined and automated. Advanced manufacturing techniques reduce manual labor and increase efficiency, which translates to lower production costs.

Reduced Material Waste

- Reusability: One of the key advantages of Aerolite carbon fiber is its thermoformability. The ability to reshape the material multiple times without degrading its properties means less waste during production. Any off-cuts or rejected pieces can be reheated and remolded, minimizing material loss.

- Precision Manufacturing: Advanced manufacturing technologies allow for more precise control over the production process, ensuring that materials are used more efficiently and reducing the amount of waste generated.

Economies of Scale

- Increased Production Volumes: As the demand for more affordable carbon fiber grows, manufacturers can produce Aerolite carbon fiber in larger quantities. Higher production volumes lead to economies of scale, where the cost per unit decreases as the scale of production increases.

- Broader Market Reach: By making carbon fiber more affordable, Aerolite opens up new markets and applications. This increased demand supports higher production volumes, further driving down costs.

Technological Innovations

- Advanced Manufacturing Techniques: Technological advancements in the production of carbon fiber composites have made the process more efficient and less costly. Techniques such as automated fiber placement (AFP) and automated tape laying (ATL) reduce labor costs and increase production speed.

- Improved Resin Systems: Innovations in resin chemistry have led to the development of more cost-effective and efficient thermoplastic resins. These new resins Naa Songs are easier to process and require less energy, contributing to overall cost reductions.

Supply Chain Optimization

- Better Raw Material Sourcing: Aerolite carbon fiber benefits from improved sourcing strategies for raw materials. By optimizing the supply chain and negotiating better terms with suppliers, manufacturers can reduce the cost of raw materials.

- Localized Production: Setting up production facilities closer to key markets reduces transportation costs and lead times. This localization helps lower overall production costs and improves responsiveness to market demands.

Sustainability and Recycling

- Recyclability: The thermoplastic nature of Aerolite carbon fiber makes it easier to recycle compared to traditional thermoset carbon fiber. Recycling reduces the need for virgin materials, lowering production costs and environmental impact.

- Sustainable Practices: Adopting sustainable manufacturing practices not only helps the environment but also reduces costs. Efficient energy use, waste minimization, and sustainable sourcing all contribute to making Aerolite carbon fiber more affordable.

Conclusion

Aerolite carbon fiber stands out as a cost-effective alternative to traditional carbon fiber, thanks to its streamlined production process, reduced material waste, economies of scale, technological innovations, and optimized supply chain. By leveraging these factors, Aerolite offers high-performance carbon fiber at a more accessible price point, opening up new possibilities across various industries.